Complex machining problems often require creative, custom solutions. RobbJack has been the “go to” supplier of solid carbide tools for over 50 years, with a proven history providing incredibly effective solutions.

RobbJack delivers special tools made to tight tolerances with application-specific carbide grades and geometries as an engineered solution. Our engineers partner with your product development team, providing robust support with timely feedback and innovative designs. RobbJack custom and modified tools reduce or eliminate the need for secondary operations, and are known for their long life, often outperforming and outlasting competitors on a scale of four to one. Let our team help find the right solution for your challenging problem.

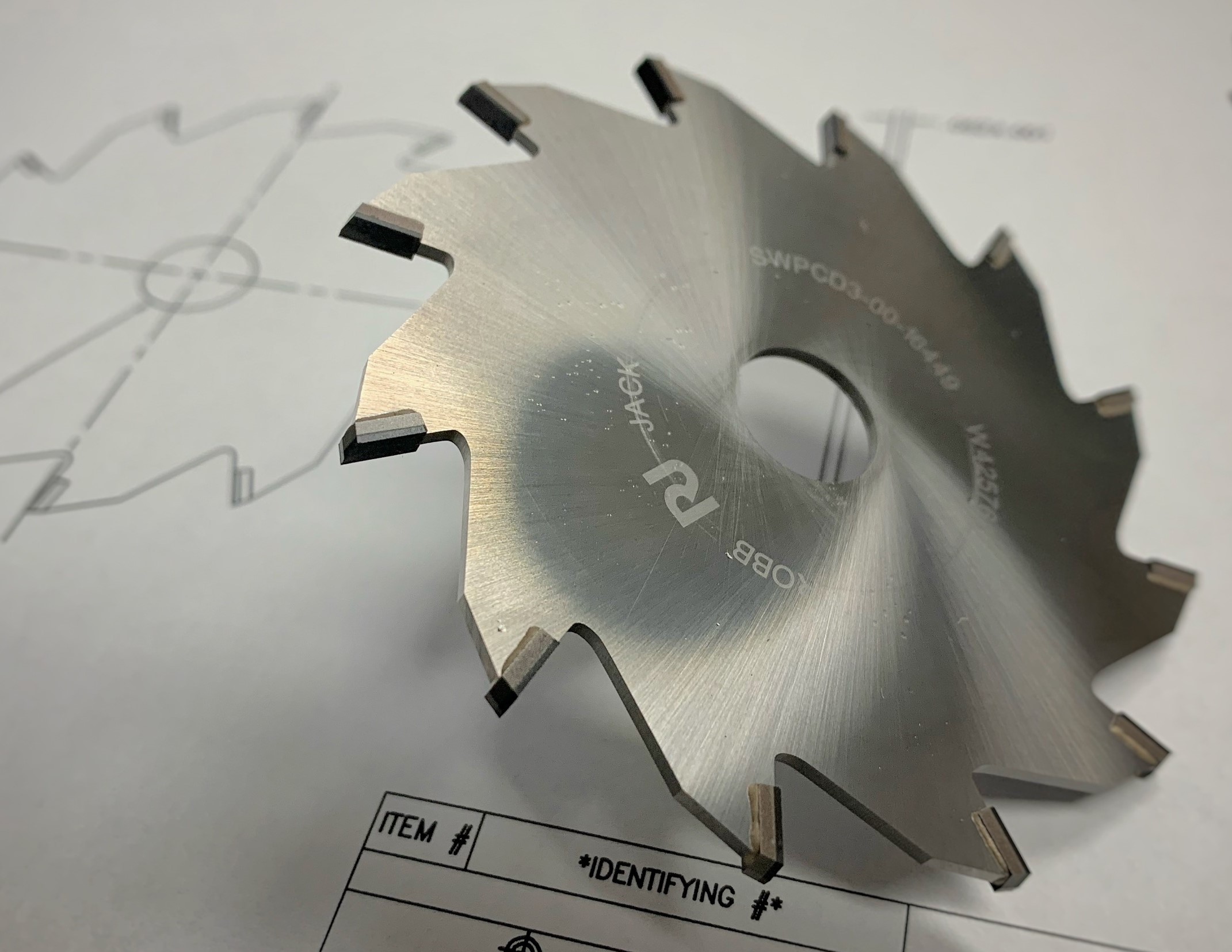

NEW – PCD Tipped Slitting Saw

- Ultra-shear geometry for minimal burr in composites

- Minimal delamination or uncut fibers

- Re-tip and re-lap PCD tips at a fraction of new cost

- 1 pass replaces carbide saw taking 3 passes in carbon filled PEEK. PCD tool gives a 50:1 advantage in tool life.

Call RobbJack with your application requirements!

NEW – PCD Hole Saw

- PCD tipped/high rake geometry for ultra-fast cutting and clean cutting of composite materials

- Minimal delamination or uncut fibers

- Extreme tool life, including re-tipping and re-lapping at a fraction of the cost of new

- Can cut cycle time in half over grit-style hole saws

Call RobbJack with your application requirements!

Composites Dovetail

- Combined 3 tools into 1

- Eliminated trimming operation to match CAD file

- Ability to diamond coat for Carbon Fiber Composites

- Custom tool used for airplane structure parts

- Bevels and trims in one operation

- Reduced the cycle time by 5 days

- Cost savings of $956,800+ per year

Composites Reamer Counter Sink

- Used with aircraft Micro-stop tooling

- Diamond coated for long life

- Reams and countersinks in one operation

- One-piece solid carbide design for tighter tolerances

- Cost savings $38,000

Composites Perforation Tool

- Sound reduction perforation tools designed for airplane engine nacelles

- Diamond coated for maximum tool life

- Makes up to 80,000 holes in fiberglass

- Produce up to 40,000 holes in carbon fiber

- $246,500 cost savings

Drill Reamer P810-R Series

- Drill and Ream in one operation.

- Diamond coating for superior tool life in abrasive materials

- Used CNC and Manually

- Eliminates delamination and uncut fibers in Carbon Fiber (CFRP) composites.

- Can be made in down-shear versions for manual operations. This will stop the tool from pulling itself through the material when piercing through

Nut Plate Drills

- Made from a single piece of solid carbide with revolutionary carbide threads

- Increases tool life

- Tighter tolerances

- Eliminates TIR

- Can be diamond coated because it is solid carbide

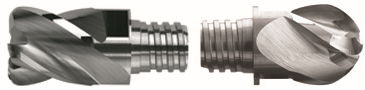

Threaded Solid Carbide Replaceable Tip

- Made with problem solving geometries to eliminate chatter, variable helix, polished flutes, coatings, and application specific geometries

- Can be used in many existing tool holders

- Can be diamond coated

- Best used in applications that would normally require long carbide tools

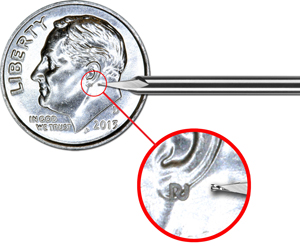

Custom Miniature End Mills

Custom Solid Carbide Slitting Saws

- Special Rocket Engine Liner Saw Geometries

- Specifically designed to cut thousands of slots faster than any other saw

- Feedrates up to 400 IPM at depths 10x saw thickness