Increased Die/Mold Tool Life

ABSTRACT

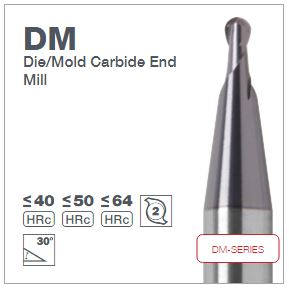

The new carbide material and new coating combination in RobbJack’s DM/MDM Die/Mold Carbide End Mill lasts 450% longer than comparable carbides and coatings designed for hard metal applications—and reduces wear by 909%.

THE PROBLEM

Hard milling applications are becoming more complex with tighter tolerances. Poor tool life requires tool changes in the middle of a job, magnifies difficulty and leads to scrapped parts.

THE TEST

Tests were conducted in D2 58 HRc, pitting comparable carbides and coatings against our new DM/MDM Die/Mold Carbide End Mills. We compared tool life and tool wear.

THE RESULT

Typical tools designed for hard metal machining had a wear land or deep notches of .0275”. The new RobbJack DM/MDM series tool outperformed every test tool with a smooth wear land of only .0025”. That’s a whopping 909% less wear.

The RobbJack DM/MDM with revolutionary new carbide and coating lasted so much longer than any other tool we were able to cut molds in difficult material 450% longer—completely eliminating the need to switch tools midway through and hope for the best. The new tools generated less heat, held size, and cut the part within tolerance.

Additional Details

- Better finishes that eliminate or reduce the need for polishing

- Tighter tolerances and longer lasting in difficult areas like parting lines

- Great for materials up to 70 HRc

- Higher temperatures

- Reduced cycle times

- Excellent precision

- Dry cutting ability

Before: Typical hard metal carbide grade and coatings for molds.

After: New revolutionary carbide grade and coating. “The one to get it done.”