Aluminum in Automotive

Abstract

When an automaker switched to aluminum, only RobbJack met the machining requirements where over 20 other toolmakers failed.

The Problem

In pursuit of performance and fuel efficiency, automakers are increasingly switching from heavy steels to lighter aerospace aluminum for everything from body panels to door frames. An American light duty truck manufacturer recently made this switch. It needed consistent performance within demanding parameters: to cut the cycle times in half by more than doubling the feed rate.

Over 20 toolmakers tried—and failed—on multiple counts:

- Their tools vibrated and chattered against thin walls.

- Targeted cycle times and feed rates caused chip packing and tool breakage.

- Extreme burring required secondary operations.

- Tools slipped and pulled out of tool holders.

Then RobbJack took on the challenge.

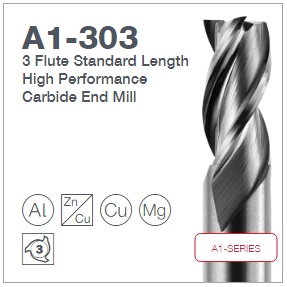

Our Solution: The A1-303 series, designed specifically for aluminum

This powerful tool had all the features needed to deliver the goods, including:

- Patented geometry to eliminate chatter and vibration

- Superior chip removal

- H5 shank tolerance

- Better gripping force in the tool holder

The Result

This powerful tool had all the features needed to deliver the goods, including:

- The RobbJack A1-303 was the only tool series that could meet the design and performance benchmarks required.

- It allowed faster feed rates, increased performance and longer tool life.

- Not one has ever pulled out of a high quality tool holder.