New Aerospace Materials Require New Cutting Tools

Our “W”-tipped drill cuts clean holes on CFRP-reinforced materials, compared to the rough edges left by conventional cutting tools.

Our W-Tipped Drill cuts clean holes on CFRP-reinforced materials

Our “W”-tipped drill cuts clean holes on CFRP-reinforced materials, compared to the rough edges left by conventional cutting tools.

“We have tools that reduce the amount of horsepower that’s consumed so you can remove more cubic inches per minute with the same amount of horsepower.” – Mike MacArthur

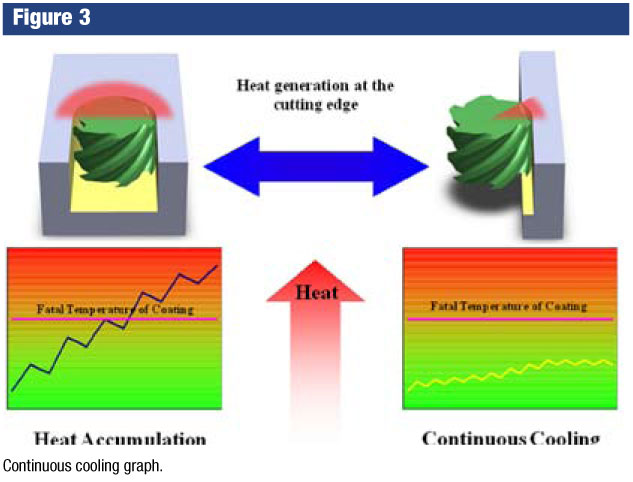

This end mill design enables it to vibrate at the same frequency as the workpiece, preventing vibration from turning into chatter.

When the right cutting tool, toolholder, cutter paths and machining parameters are applied intelligently, a shop may have more capability to mill titanium effectively than it recognizes.

Quick, easy speed and feed calculations for any material, grade or machining application in both metric and standard.

Choosing the right tool will pay huge dividends in the quality, repeatability and the overall success of a job. This article discusses the different types of materials, which tools to choose, and how to use them.

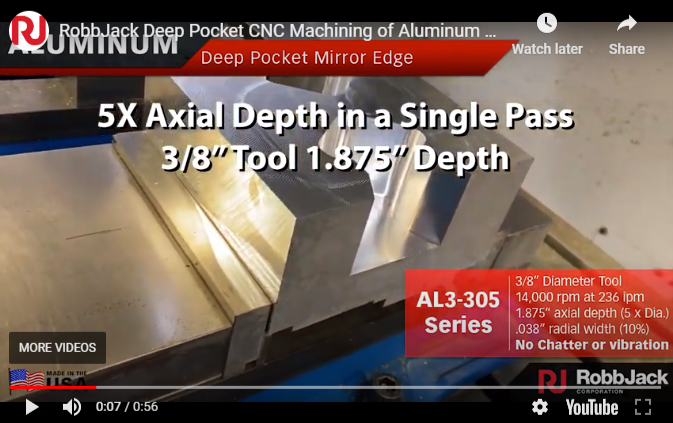

With the right tools and a little know-how, you can remove a lot of metal in a shorter time than you thought possible.

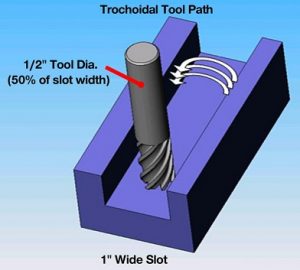

Trochoidal toolpaths are available on most CAD/CAM systems, yet are rarely used or even known. By using trochoidal toolpaths and hybrid trochoidal toolpaths you can successfully machine exotic materials.

Many of the proven technologies used for mold and die machining can also be used in difficult to machine aerospace materials.