Titanium Tool Selection

The proper way to choose a titanium tool. Also programming techniques and more. Click here.

When Nothing Less Will Cut It

RobbJack tools are known for their long life, often outperforming and outlasting competitors on a scale of four to one. This not only lowers tool cost over time, but also increases factory productivity since the tools spend more time in operation and less time being replaced.

The proper way to choose a titanium tool. Also programming techniques and more. Click here.

Carbide or steel shank? What’s the right order? How do I control heat? What’s the proper programming technique? All this and more here.

Machining aluminum? Here’s what you need to know to do the job right… the tools, the technique, the process

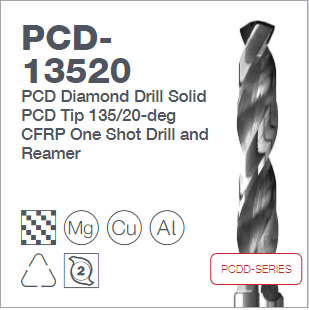

Composite tools present their own special challenges, such as proper fixturing and vibration. And of course, it always helps to get the best tool for maximum life

Carbon Fiber and other composite materials are very difficult to cut with out delamination, uncut fibers, or poor tool life. This webinar teaches techniques to solve those problems. This webinar covers diamond coated carbide, PCD, and carbide routers and drills.

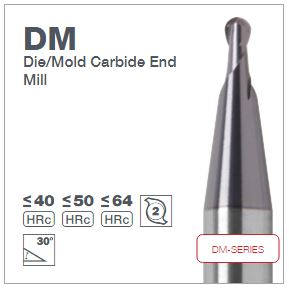

Many people feel that hard metal machining is a black art, but with a few basic principles it is not only profitable but also a straightforward machining process.