Die Mold Tool Selection

RobbJack offers a range of solid carbide cutting tools for the die and mold industry:

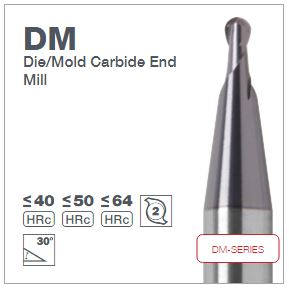

- Ball End, DM/MDM series

- For hardness up to 62 HRc

- Can be PVD coated for improved wear resistance

- Materials are 6-12% cobalt

- Greater stiffness than steel shanks with a max L:D ratio of 11x, where steel is limited to 4x

- Available 1/32″ to 1/2″ (0.5mm to 12mm)

- Applications include roughing, semi-finishing, finishing, and helical boring

- Bull Nose, HM/MHM series

- For hardness up to 60 HRc

- Can be PVD coated for improved wear resistance

- Provides larger diameters with small corner radii

- Typical uses include semi-finishing and finishing with straight sides and corner radii

- Square End, XG/MXG series, XF/MXF series and SS/MSS–SR/MSR series

- For hardness up to 40 HRc

- Can be PVD coated for improved wear resistance

- 6-12% cobalt material

- Side milling

- Uses include roughing, semi-finishing, finishing flat areas, slotting, and pocketing

- Die mold tools are available with extended reach lengths

- Draft angles provide greater strength

- Straight neck for machining against walls

- Controlling heat generation in die/mold machining applications

- Get the heat out of the chip – Use the appropriate speeds and feeds for the material and tool

- Mist coolant is a good method that avoids thermal shocking the tool

- High pressure air

- Select the proper tool coating

Contact a RobbJack specialist for more help with your die/mold application!