Flat bottom drills are an excellent solution for counterbores or when you need to remove the angle left from a typical drill and a flat floor is required.

RobbJack 2 flute solid carbide flat bottom drills

Also used to drill into curved or angled surfaces where a typical drill would walk, our flat bottom drills come in solid and thru coolant versions with and without DLC coating. Flat bottom drills are an excellent choice when a burr-free hole is required when parts have crossholes or intersecting geometry. If you need to drill a partial hole that does not make 360 degrees contact around the drill, flat bottom drills are the best choice when the drill is partially off the part. The longer a drill is, the higher the chance that it will walk. Start a hole with the shorter length flat bottom drill first before using the long length drill

“We can’t believe the difference using RobbJack’s flat bottom drills! We are getting over 300,000 holes per tool! That is over a 10 times improvement in tool life. We should be leasing these tools they last so long!!!!”

-Major precision level manufacturer“We love RobbJack’s flat bottom drills! They out-perform every other tool we have tried in nasty A286”

-Large aircraft manufacturer

The FBD Series in Action

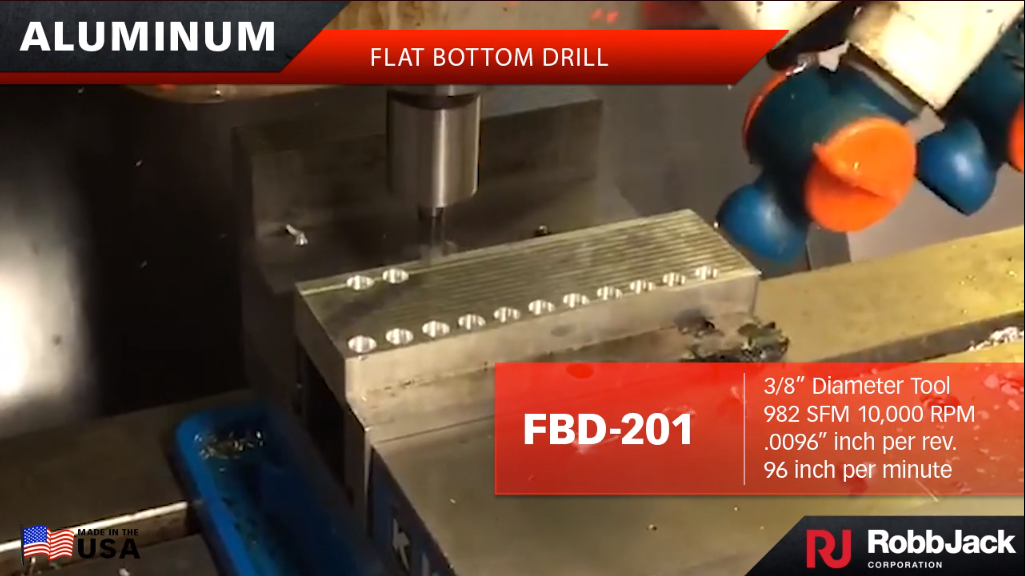

This video shows an FBD-201 drill creating 3/8″ holes in aluminum at 96 IPM at 10,000 RPM and 982 SFM.

Application Guides

The FBD series application guide is available as a PDF HERE!