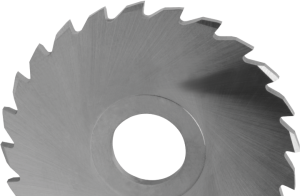

Solid Carbide Saws

Don’t settle for a slitting saw that “gets the job done.” Choose exactly what you need to do the job right. RobbJack offers an extensive selection of premium carbide slitting saws that deliver high speed, superior finishes and unsurpassed precision. Thicknesses are available from .002” to .250” with geometry in both course and fine teeth for aluminum, stainless steel, titanium and all machinable materials.

K-Series Saws

RobbJack solid carbide slitting saws are made to the tightest tolerances. K-series saws are best for deep slots or saw gang operations and have more concavity, alternate tooth chamfers and a flat and parallel hub. Alternate Tooth Chamfer is an alternating 45-degree grind on the teeth of the saw. It helps keep the saw from binding and aids in chip evacuation. Alternate Tooth Chamfer should be used on saws when the depth of cut is more than 5X the saw thickness, and the saw is thicker than 0.020″.

Saw Hubs

A saw hub is a section of the saw where there is no concavity. It is a flat and parallel area that is the same thickness as the cutting tooth, near the ID of the saw where the flange contacts the saw. Hubs should be used in cuts deeper than 3X the saw thickness, providing better surface contact with the arbor flange to reduce slippage and ensure saws run very true.

Keyways

To eliminate slippage problems on saws greater than 0.125″ thick in high torque cuts, keyways can be added. When saw thickness is less than 0.125″, keyways can cause stress risers and cracks, so try adding a saw hub first.

Find all of RobbJack saws, including the K-series, here.

Download RobbJack’s current Saws Guide here.

Find a RobbJack distributor here.