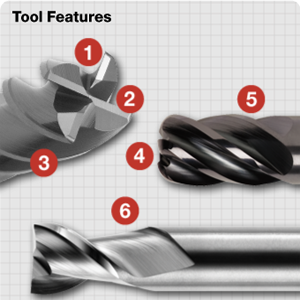

- Radial Rake controlled within +/-1° to ensure consistent tool performance

- Center cutting on every two flute, three and four flute end mills

- Web, cheek, ramp and helix angle ground to geometrically controlled tolerances to ensure faster chip flow

- Geometrically controlled ends, meet or exceed NAS specifications

- T.I.R. controlled to 1/3 industry standards to ensure equal flute wear

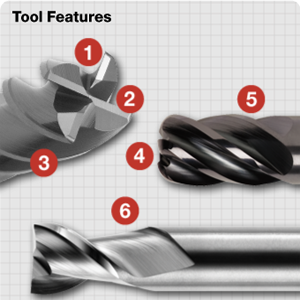

- O.D. tolerances of +.001”/-.000” on selected series, with primary relief angle super finished to 4 to 6 RMS on all end mills

- Weldon Shanks on selected series

- Overall length ground and corners chamfered on all shanks to prevent scoring of tool holders

- Tightest Shank Tolerances in the Industry

- -.0001”/-.0002” as Standard

- -.002/-.005 in Metric sizes

|

|