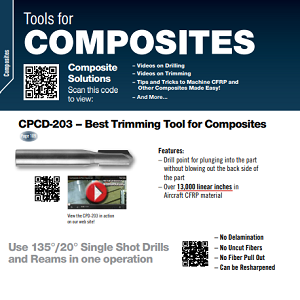

Delamination and uncut fibers are just a few of the special challenges presented by routing composite materials. For every application, there’s a RobbJack composite tool to get the job done right and done fast. Search for a distributor near you.

How to Machine Carbon Fiber

Many companies struggle with machining of new composite materials. Common problems are poor tool life, delamination of layers, and long cycle time. The presentation is set up to give tricks and tips to overcome most of the problems encountered machining modern composites.

Case Study: Carbon Fiber in Aircraft

ABSTRACT: When drilling carbon fiber reinforced polymer (CFRP) wing spars, an aircraft manufacturer struggled with poor quality cuts and expensive scrap until switching to RobbJack’s new Single Shot PCD diamond drill.

Read more about our solution to this problem HERE.

Composite Tips and Tricks

Composite tools present their own special challenges, such as proper fixturing and vibration. And of course, it always helps to get the best tool for maximum life. Read more HERE.

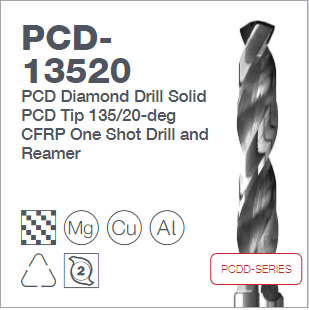

Routing Carbon Fiber Epoxy Composite Material with a RobbJack PCD Diamond Router

Drilling of CFRP Carbon Fiber Epoxy using a RobbJack PCD Drill

Problem Solving Tools for Composites

RobbJack routinely solves complex problems with application-specific special tools. Click here to see more.

Composites Applications Guide

Tools for working with composite materials. Click here for the application guide, or search for composite cutting tools here.