Innovative End Mills and Coatings for superior performance in firearms manufacturing

The Firearms Industry is experiencing high demand and looking to increase output without having to purchase more capital equipment. Manufacturers turn to RobbJack’s proven solutions for high-performance firearms machining in everything from aluminum to hardened steel to increase output by up to 500% on your current equipment.

Aluminum Firearm Parts:

AL3 Series High-Performance End Mills

The AL3 carbide end mill allows you to machine deeper parts, deep profile cuts in a single pass with minimal chatter and vibration. High-Speed Machining of deep pocket aluminum CNC machined parts up to 5:1 Length to Diameter ratio without vibration or chatter at 500% faster rates. The H4 shank tolerance is the best in the industry on all sizes and comes standard with Anti-pullout shank technology to eliminate tools pulling out of tool holders.

AL3 tools are available with different corner radii and cutting lengths for AR components – uppers, lowers, and handguards. One firearms customer using an AL3-series end mill achieved a 725% cycle time reduction on an AR handguard.

Steel, Titanium, and Stainless Tools

Made of RobbJack’s Tuffy Grade Carbide, our XF-series and XG-series end mills are engineered with a unique geometry to make tough hard metal jobs easy and efficient. The speeds and feeds and cubic inch removal rate of the XF series are typically five to ten times faster than traditional machining. XF-series tools are best used for finishing and light cuts on slides, frames, bolts, and many other parts available in many different radii. XG-series tools are used for roughing and finishing on slides, frames, bolts, and many other parts. XG-BN tools are used roughing and finishing for fluting of barrels and bolts or anywhere a ball end mill is needed to blend or contour parts.

FB-series 2 flute solid carbide flat bottom drills

Flat bottom drills are an excellent solution for counterbores or when you need to remove the angle left from a typical drill and a flat floor is required. Also used to drill into curved or angled surfaces where a typical drill would walk, our flat bottom drills come in solid and thru coolant versions with and without DLC coating. Flat bottom drills are an excellent choice when a burr-free hole is required when parts have cross holes or intersecting geometry. If you need to drill a partial hole that does not make 360 degrees contact around the drill, flat bottom drills are the best choice when the drill is partially off the part. The FBD Series includes two versions; one for non-ferrous materials, and another for difficult to machine materials.

Miniatures and Etching Tools

Get the most accurate and long-lasting carbide miniatures on the planet with SS and SR series micro end mills and etching tools. Used for engraving, deburring, checkering, chamfering.

- Cutting diameters from 0.005″ every .001″ up to .062″.

- Tolerances in microns smaller than a human hair.

- Hand-select diameters to the nearest 0.0002″.

- Primary relief angles to maximize quality machining performance.

The ET-Series etching tools are available with plunge, ball, and standard tips and increase the speed and quality of etching operations.

Ultra-precision Solid Carbide Slitting Saws

RobbJack offers an extensive selection of premium carbide slitting saws that deliver high speed, superior finishes, and unsurpassed precision. Thicknesses are available from .002” to .250” with geometry in both coarse and fine teeth for all firearms materials.

- C12-0625-16-36 is commonly used for cutting triggers, slides, frames, grooves, and rails

K-series saws are best for deep slots or saw gang operations and have more concavity, alternate tooth chamfers, and a flat and parallel hub. Alternate Tooth Chamfer is an alternating 45-degree grind on the teeth of the saw. It helps keep the saw from binding and aids in chip evacuation.

Physical Vapor Deposition (PVD) Coatings

Crystallume PVD division of RobbJack specializes in coatings for functional applications. Our coating expertise covers the range of materials from aluminum to high-speed steel to tungsten carbide, with many applications in the firearms industry. PVD firearms coatings offer these advantages:

- Easy to clean

- Superior wear resistance

- Improved cycling rates

- Enhanced corrosion protection

- No tolerance build-up (microns thickness)

- Less maintenance

Diamond-Like Carbon (DLC)

DLC is a very hard surface superior to all other PVD coatings. The DLC coating is very adaptable and has an excellent appearance that mirrors the material being coated. You can get a dull tactical finish on media blasted parts or a mirrored finished on polished parts. The DLC coating has excellent corrosion resistance and aids in the ease of cleaning of your finished product.

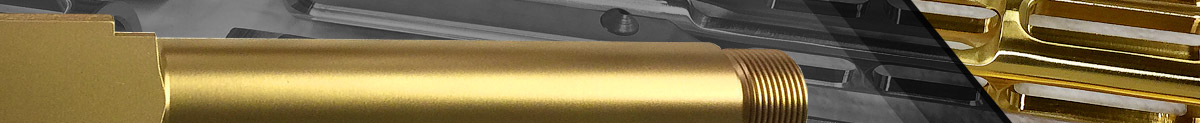

Titanium Nitride

A general-purpose coating which can reduce abrasive and adhesive wear. Its appearance can range from a near-gold to a copper color, to the silver-blue color typically found in the marketplace.

Custom etching of your parts available after PVD!!